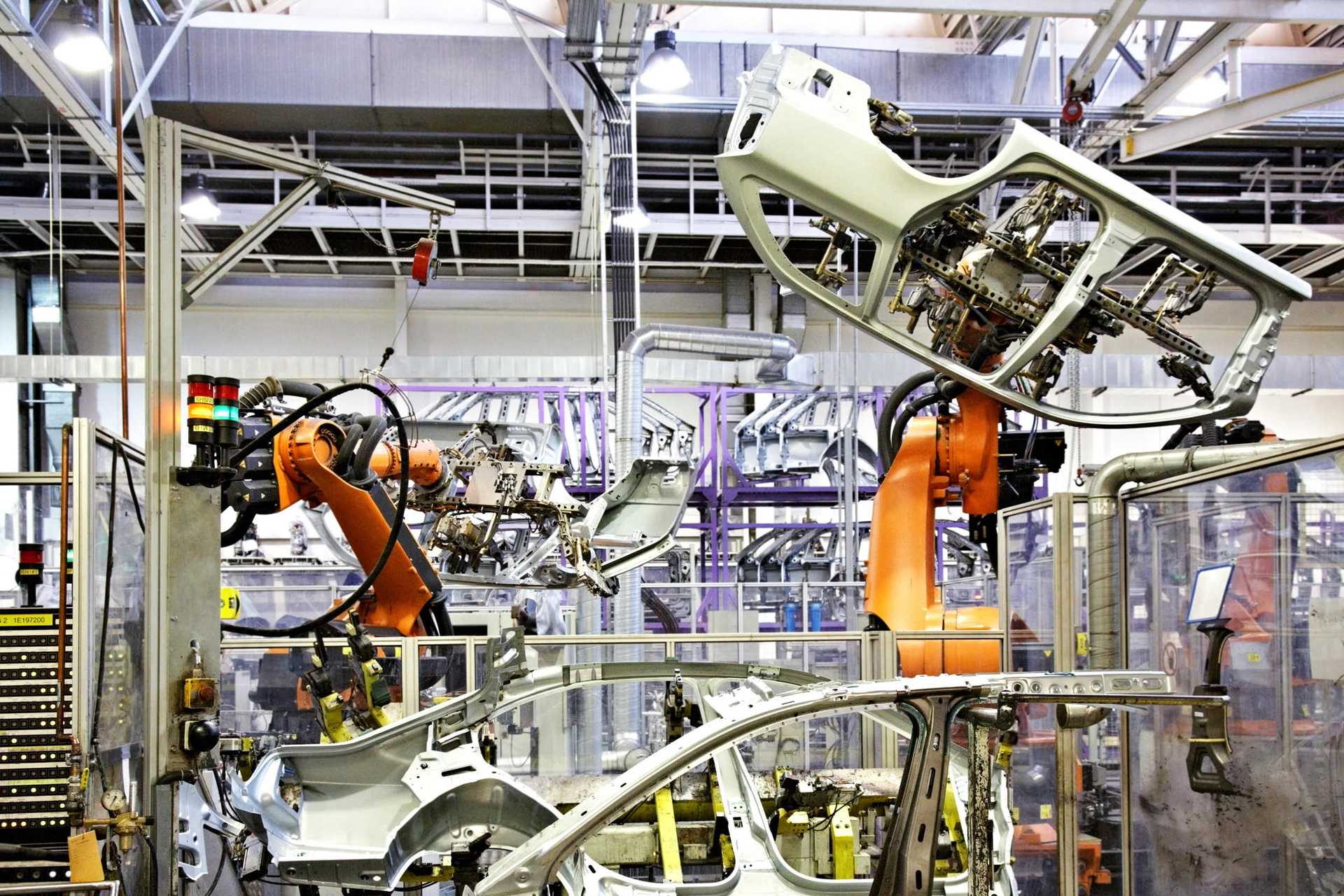

Manufacturing (Custom/Discreet)

Managing the collision of operational complexity and business volatility requires precision. We help custom and discrete manufacturers digitize tribal knowledge, stabilize production, and gain real-time visibility across the entire shop floor.

Eliminating Bottlenecks with Real-Time Performance Insights

Custom and discrete manufacturers are under intense pressure as operational complexity collides with a rapidly changing business environment. Volatile demand, shorter product lifecycles, and increasing product customization are stretching traditional planning and shop-floor processes to their limits. Many manufacturers still rely on disconnected systems, spreadsheets, or manual tracking, making it difficult to maintain real-time visibility into production status, quality issues, and bottlenecks. At the same time, global supply chain disruptions—ranging from supplier instability to longer lead times and geopolitical uncertainty—are forcing manufacturers to operate with less margin for error while managing inventory more strategically.

Staffing and productivity challenges further compound these issues. An aging workforce, skilled labor shortages, and high turnover rates are eroding tribal knowledge and putting added strain on remaining employees. New hires often require extensive training, while experienced operators are pulled away from value-added work to manage exceptions and firefighting. Without standardized, digital processes and real-time performance insights, productivity suffers and continuous improvement stalls. To stay competitive, custom and discrete manufacturers must find ways to do more with fewer resources, improve workforce effectiveness, and build resilient, data-driven operations that can adapt quickly to ongoing supply chain and market uncertainty.

Transform Your Manufacturing Performance

Consult with our specialists to implement scalable digital systems that reduce tribal knowledge dependency and optimize your custom production cycles.